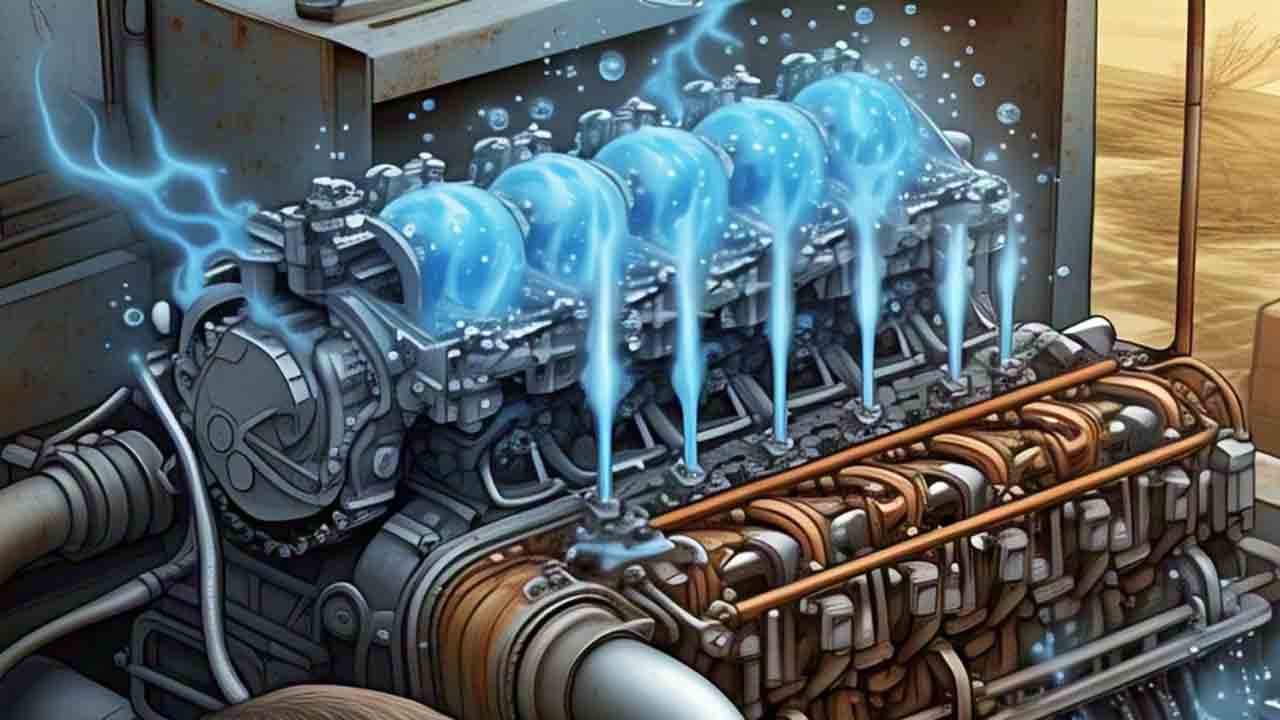

Dieselspecialists – Breathing new life into diesel technology, industry leaders Yanmar and Mahle are pioneering the transformation of conventional diesel engines into clean, hydrogen-powered systems. As the global pressure to reduce carbon emissions intensifies, these innovations present a promising bridge between traditional combustion and a sustainable energy future.

Yanmar, a Japan-based manufacturer renowned for its industrial engines, has unveiled a hydrogen-powered version of its 4TN101 diesel engine. This move marks a significant milestone, allowing existing engine platforms to evolve into zero-emission alternatives without the need for a complete mechanical overhaul. Meanwhile, German engineering firm Mahle is also making waves by developing retrofit solutions to convert older diesel engines particularly those used in trucks and agricultural machinery into hydrogen-fueled power units. This effort is not only cost-effective but also accelerates the transition toward cleaner technology in heavy-duty applications.

Breathing new life into the diesel segment doesn’t mean abandoning it entirely instead. It’s about enhancing what already exists. Hydrogen, as a zero-carbon fuel, offers a viable path to decarbonize internal combustion engines, especially in sectors where full electrification remains challenging.

“Smart Helmets 2025: Ride Safer, Ride Smarter”

Hydrogen combustion engines differ from traditional diesel engines in one crucial way: while they operate similarly in terms of mechanical structure, they emit only water vapor instead of harmful nitrogen oxides or particulates. This advantage makes them an ideal interim solution as electric vehicle infrastructure continues to scale. Companies like Mahle are investing heavily in research and development to ensure these hydrogen adaptations can match the performance and durability that industries expect from diesel-powered machines.

Breathing new life into diesel engines through hydrogen conversion is not just an environmental strategy. It’s also a smart economic move. Instead of scrapping millions of existing diesel engines worldwide. This method preserves infrastructure investments and extends the lifespan of machinery with a green twist.

The implications are far-reaching: construction equipment. Freight vehicles, and agricultural machines sectors heavily reliant on diesel could all benefit from this innovation. Yanmar’s initiative, for example, aligns with broader efforts in Asia to decarbonize transportation and manufacturing without sacrificing industrial growth. By retrofitting rather than replacing, companies reduce waste, minimize costs, and maintain operational familiarity while transitioning to cleaner fuel.

As more governments and industries commit to net-zero targets. Hydrogen-powered diesel conversions could play a vital role in balancing progress and practicality. And with innovators like Yanmar and Mahle leading the way. The world may soon find that breathing new life into old engines is the key to a greener future.

“A Final Goodbye: Pope Francis Laid to Rest”

Dieselspecialists - Diesel repairs are entering a new era with the introduction of cutting-edge additive manufacturing (AM) technology, commonly known…

Dieselspecialists - The automotive industry is witnessing a groundbreaking shift with the integration of AI and Digital Twins, reshaping how…

Dieselspecialists - When it comes to diesel engine technology, one of the most fundamental distinctions lies in the choice between…

Dieselspecialists - Diesel trouble signs are often subtle at first, but they indicate potential issues that, if left unresolved, could…

Dieselspecialists - Revolutionizing Diesel Parts has become the hallmark of innovation in the automotive sector, especially within the diesel engine…

Dieselspecialists - Diesel Engines Drive On even as passenger car sales using diesel technology continue to decline. According to the…