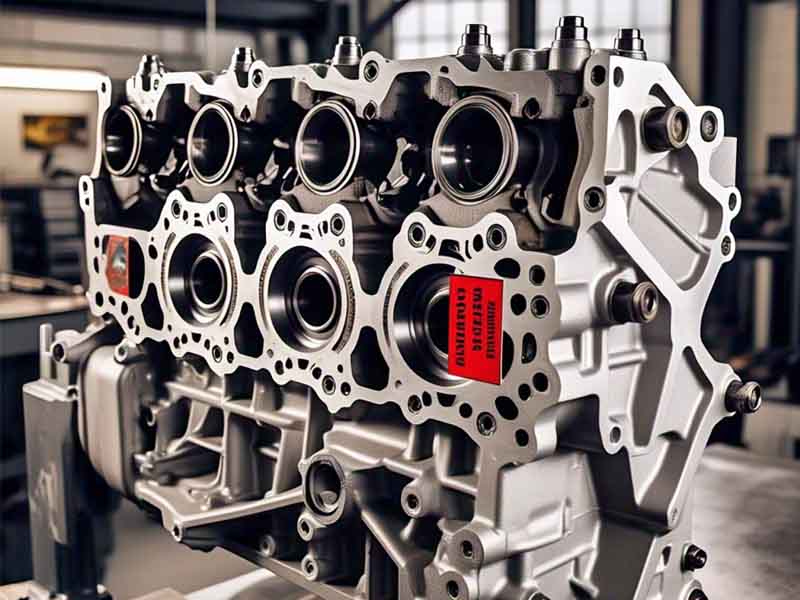

Dieselspecialists – Remanufactured Diesel Parts are gaining widespread attention as a cost-effective and environmentally friendly alternative to new components. With rising demand for sustainable solutions in the automotive and industrial sectors, remanufacturing has emerged as a viable option for those seeking high-quality diesel parts without the high price tag.

The process of remanufacturing involves restoring used or worn-out components to their original specifications, ensuring they function like new. This method not only reduces costs but also helps lower environmental impact by minimizing waste and conserving raw materials. As industries continue to prioritize sustainability, Remanufactured Diesel Parts are expected to play a key role in shaping the future of diesel engine maintenance and repair.

One of the biggest advantages of Remanufactured Diesel Parts is their affordability. Compared to brand-new components, remanufactured parts often come at a significantly lower price, making them an attractive choice for businesses and individuals looking to reduce maintenance expenses. Despite the lower cost, these parts undergo rigorous testing and quality control measures to ensure they meet or exceed industry standards.

“Smart Helmets with HUD: The Future of Riding”

Manufacturers use advanced techniques to restore worn-out components, replacing damaged or outdated elements while maintaining the integrity of the original design. This approach ensures that users receive durable, high-performing parts at a fraction of the cost. Fleet operators, repair shops, and vehicle owners increasingly recognize the value of remanufactured options. Further driving their adoption in the market.

The remanufacturing process significantly reduces waste and conserves resources by giving old components a second life. Instead of discarding used diesel parts into landfills, remanufacturing allows them to be refurbished and reused. Cutting down on unnecessary production and energy consumption.

By choosing Remanufactured Diesel Parts. Industries contribute to a more sustainable future by reducing carbon footprints and lowering overall environmental impact. As global regulations push for greener manufacturing practices, the remanufacturing industry is poised to expand. Offering innovative solutions that benefit both businesses and the planet.

With cost savings, guaranteed quality, and environmental advantages. Remanufactured Diesel Parts continue to prove themselves as a smart and responsible choice for diesel engine maintenance. As more industries embrace this approach, the future of remanufacturing looks brighter than ever.

“Honoring Victims of Slavery on March 25”

Dieselspecialists - Revamping internal combustion engines (ICE) has become an urgent need in the automotive industry as environmental concerns continue…

Dieselspecialists - Maximizing diesel engine performance begins with understanding the critical role of turbochargers. These devices enhance engine power by…

Dieselspecialists - Durable Diesel Parts play a crucial role in maximizing vehicle performance and longevity. Choosing high-quality engine components can…

Dieselspecialists - Clean Diesel has long been recognized for its efficiency and durability, making it the preferred choice for commercial…

Dieselspecialists - Variable Geometry Turbocharger (VGT) is transforming modern engine performance by optimizing airflow dynamics based on real-time engine needs.…

Dieselspecialists - Built to Last, diesel engines have earned a reputation for their remarkable durability and endurance. Unlike gasoline engines,…